The Importance of a Microchip in Winter

Crafting microchips, or semiconductor manufacturing, is no simple task. It's a dance of precision where even the tiniest misstep can derail the entire process. Every phase, from the initial blueprint to the final quality checks, requires an almost obsessive focus on accuracy. Engineers use techniques like lithography to etch microscopic pathways, building transistors smaller than a grain of sand that somehow power our digital world.

What many don't realize is how much these factories resemble science fiction movies. Workers in sterile bunny suits move through ultra-clean rooms where a single speck of dust could ruin millions of dollars worth of product. The air filtration systems alone cost more than most office buildings. This marriage of cutting-edge technology and human expertise creates the magic behind every device we use daily.

The Impact on Modern Electronics

Try imagining your morning without microchips. Your alarm wouldn't sound, your coffee maker wouldn't brew, and your smartphone would be a useless slab of glass. These tiny silicon squares have quietly revolutionized human civilization more profoundly than the industrial revolution.

From the pacemaker keeping someone's heart beating to the traffic lights managing your commute, microchips operate invisibly everywhere. Their reliability in extreme cold makes them indispensable for everything from Arctic research stations to space exploration.

Applications Across Industries

The true marvel lies in how microchips adapt to different environments. In hospitals, they power MRI machines that can detect tumors. In your car, they control the anti-lock brakes that prevent skids on icy roads. Airplanes rely on them for navigation through winter storms when visibility drops to zero.

Even the food industry depends on microchips - they regulate temperatures in refrigerated trucks delivering groceries during blizzards. This versatility explains why a shortage can paralyze multiple sectors simultaneously.

Energy Efficiency and Miniaturization

Engineers face an incredible challenge: packing more power into smaller spaces while using less energy. The latest chips consume less electricity than a nightlight while outperforming computers that once filled entire rooms.

This miniaturization allows for medical implants that monitor patients remotely and sensors that predict avalanches before they happen. The technology keeps shrinking while its potential keeps growing exponentially.

The Future of Microchip Technology

Tomorrow's chips might use quantum physics to solve problems in minutes that would take current supercomputers centuries. Some labs are developing neuromorphic chips that mimic the human brain's efficiency.

When these next-gen chips combine with AI, we'll see smart cities that automatically adjust heating during cold snaps and self-repairing infrastructure that prevents winter blackouts. The boundary between digital and physical worlds continues to blur thanks to these advancements.

Manufacturing Challenges and Solutions

Producing these microscopic marvels isn't getting easier. A modern chip factory costs over $20 billion to build - more than most aircraft carriers. The precision required is staggering; we're now working at scales smaller than viruses.

Innovative solutions like extreme ultraviolet lithography and new semiconductor materials are pushing the boundaries of what's possible. Automation helps, but we'll always need brilliant minds to solve problems we haven't encountered yet.

Global Impact and Dependence

The pandemic revealed how vulnerable our microchip supply chains are. A delay at one factory in Asia can idle car plants in Germany and delay laptop shipments worldwide.

Countries are now racing to build domestic production, understanding that microchips have become as essential as oil was in the 20th century. Whoever masters next-generation chip technology will likely lead the global economy.

Improving the Efficiency of Winter Infrastructure Maintenance

Optimizing Energy Consumption

Winter turns buildings into energy sieves. The secret to efficiency lies in understanding heat flow patterns specific to your structure. Thermal imaging cameras reveal invisible leaks that waste more energy than leaving windows open.

Modern smart thermostats learn faster than ever. New models detect when you're away and adjust accordingly, saving hundreds annually. Don't overlook basic maintenance - a dirty furnace filter can increase energy use by 15% while shortening equipment life.

Effective Insulation Strategies

Quality insulation works like a thermos for your home - keeping warmth in and cold out. The attic often leaks more heat than walls and windows combined. Spray foam insulation expands to fill every crevice, creating an airtight seal that pays for itself in 3-5 years.

Drafty windows account for 25-30% of heat loss. Simple weatherstripping provides immediate relief, while triple-pane windows with gas fills offer permanent solutions. Even outlet covers on exterior walls can make a measurable difference in older homes.

Sustainable Heating Alternatives

Ground-source heat pumps defy winter logic by extracting warmth from frozen ground. While expensive initially, they cut heating bills by 50-70% with a lifespan exceeding 25 years. Solar thermal systems complement them perfectly, providing free hot water even in subzero temperatures.

Biomass boilers running on wood pellets offer carbon-neutral heating at competitive prices. Municipalities are adopting district heating systems that recycle industrial waste heat - an elegant solution gaining traction across northern Europe.

Future Applications and Innovations in Winter Technology

Advanced Insulation Materials for Enhanced Thermal Performance

Aerogel insulation represents a quantum leap - weighing nothing while outperforming fiberglass. NASA uses it to protect Mars rovers from -130°F nights. Coming soon to winter jackets and building panels, this frozen smoke could revolutionize cold-weather protection.

Smart Clothing and Wearable Technology Integration

Next-gen heated clothing uses graphene fibers that warm evenly without bulky wiring. Some prototypes harvest body motion to self-power, eliminating batteries. Integrated sensors monitor core temperature, alerting wearers to early hypothermia risks during outdoor activities.

Innovative Winter Transportation Solutions

Self-heating roads using embedded coils may make snowplows obsolete. Electric vehicles with predictive thermal management extend winter range by pre-warming batteries using renewable energy. Some cities test magnetic pavement that melts snow through induction heating.

Sustainable Energy Solutions for Winter Housing

Passive house designs now achieve 90% energy reduction through superinsulation and heat recovery ventilators. Some Arctic communities operate entirely on wind and solar with seasonal hydrogen storage. These models prove sustainable living is possible even in extreme climates.

Improved Safety and Security in Harsh Winter Environments

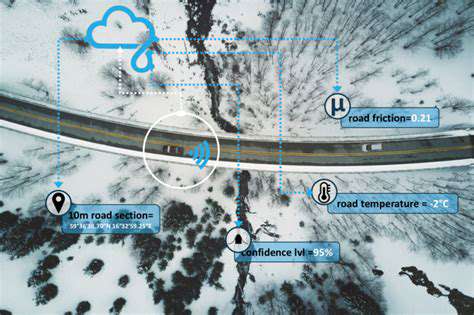

AI avalanche prediction systems analyze snowpack stability with 95% accuracy. Emergency beacons now include two-way satellite messaging for remote areas. Autonomous snowmobiles can deliver supplies or perform rescues in whiteout conditions too dangerous for humans.

Enhanced Winter Agriculture and Food Production

Vertical farms using LED lighting and hydroponics produce fresh vegetables year-round with 95% less water. Some Nordic growers use geothermal energy to create tropical microclimates for citrus fruits. These innovations could eliminate winter food deserts in northern regions.