Your ultimate resource for pet care Explore services and innovations that honor your pet's life, enhance their well-being in senior years, and address dietary and health issues with modern solutions

Deep Dive into Sustainable Self Improvement

Sep 03, 2025

Eco Conscious Calm: How Sustainability Boosts Your Mental State

Sep 03, 2025

AI and Neurodiversity: Tailored Support Systems for Unique Brains

Sep 03, 2025

Sustainable Digital Detox Challenges: A Personalized Journey to Calm

Sep 02, 2025

The Sustainable Power of Positive Psychology

Sep 02, 2025

The Green Brain: Sustainable Nutrition for Cognitive Vitality

Sep 02, 2025

AI Powered Stress Reduction for High Performance Professionals

Sep 01, 2025

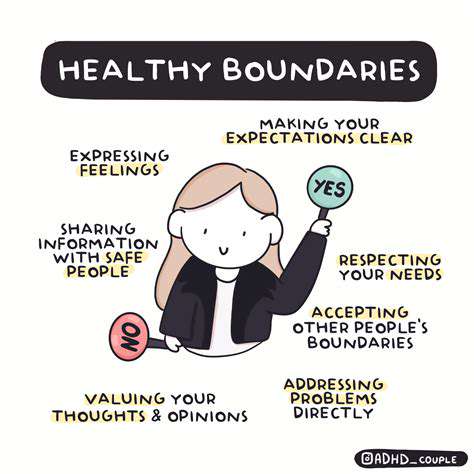

Your Guide to Setting Healthy Boundaries with Technology

Sep 01, 2025

Your Personalized Toolkit for Sustainable Happiness and Fulfillment

Sep 01, 2025

Mental Health Initiatives in Schools: Beyond the Classroom and Towards Holistic Care

Sep 01, 2025

Mental Health Initiatives in Schools: Beyond the Classroom

Sep 01, 2025

Eco Friendly Mental Wellness: Sustainable Choices for a Balanced Life

Aug 31, 2025

Customized Daily Routines for Optimal Mental Health

Aug 31, 2025

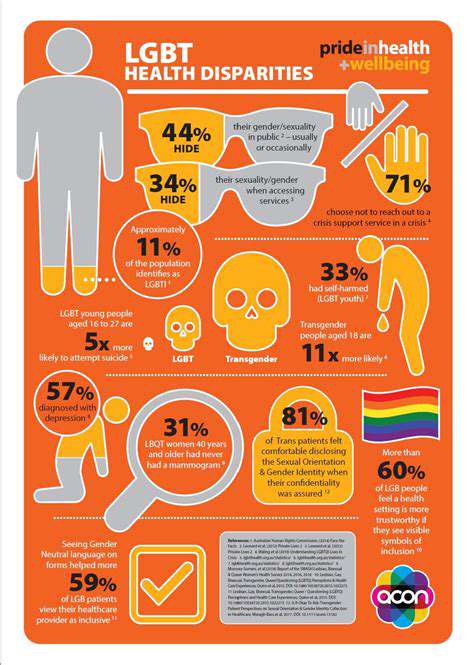

Mental Health Initiatives for the LGBTQIA+ Community

Aug 31, 2025

Genetic Wellness: How DNA Can Inform Your Personalized Health Plan

Aug 31, 2025

The Role of Technology in Scaling Mental Health Initiatives

Aug 31, 2025

Veteran Mental Health Initiatives: Honoring and Healing Our Heroes

Aug 30, 2025

Tailored Meditation Techniques for Deep Relaxation

Aug 30, 2025

Sustainable Wellness: A Holistic Perspective

Aug 30, 2025

AI Driven Personalized Meditations for Kids' Mental Health

Aug 30, 2025

Hot Recommendations

- Customized Sleep Schedules: AI Driven for Sustainable Rest

- Crafting a Personalized Productivity Plan for Mental Clarity

- Sustainable Self Compassion: Cultivating Kindness Towards Your Mind

- Sustainable Productivity Hacks for the Busy Professional

- Sustainable Wellness for Parents: Balancing Family and Self Care

- Data Informed Self Care: Designing Your Personalized Wellness Strategy

- Sustainable Wellness for a Purpose Driven Life

- AI Assisted Mindfulness: Personalized Meditations for Deeper Practice

- Building Inclusive Mental Health Services: Key Initiatives

- AI Powered Self Care: Customizing Your Routine for Maximum Impact